NWE Successfully Conducts Hyperbaric and SEM Testing for Polyester Rope Qualification

NWE is pleased to announce the successful execution of a comprehensive qualification testing campaign on a polyester rope assembly. Conducted in collaboration with an international rope manufacturer and a recognized classification society, the testing took place at a specialized facility in Norway.

The campaign featured advanced Hyperbaric Testing and Scanning Electron Microscope (SEM) Analysis as part of the final qualification process for offshore mooring applications. All testing activities adhered to internationally recognized standards, including ISO 18692, and followed applicable classification guidelines.

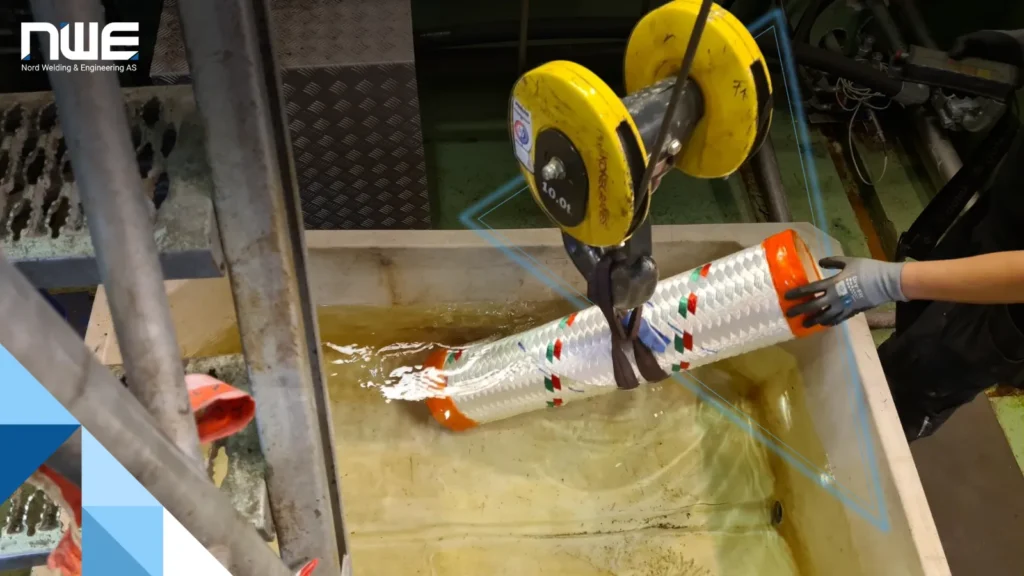

During hyperbaric testing, the polyester rope sample was subjected to pressurization up to 160 bar in both fresh water and a simulated seabed soil environment. Over a continuous 72-hour period, the rope maintained full pressure integrity, showcasing its resistance to particle ingress and mechanical fatigue.

The SEM analysis further validated the effectiveness of the internal soil filter structure. No signs of external contamination or performance degradation were detected, confirming the rope’s durability in harsh subsea conditions.

All inspection activities were performed in accordance with the approved Inspection and Test Plan (ITP), with witness and hold points observed by relevant stakeholders. The entire procedure was carried out safely and efficiently, with no non-conformances or health, safety, and environmental (HSE) concerns reported.

This successful outcome reinforces NWE’s expertise in delivering independent third-party inspection and quality surveillance services for critical offshore equipment. It underscores the company’s commitment to ensuring compliance, reliability, and high performance under extreme operational environments.

How useful was this post?

Click on a star to rate it!

0 / 5. 0