Lingshui 172 – Pioneering China’s Deepwater Gas Frontier

Independent Development, Global Standards

Located in the South China Sea, Lingshui 172 marks China’s first independently developed deepwater gas field. With NWE providing continuous inspection and oversight across Asia and Europe, this project reflects the highest levels of offshore engineering, quality control, and execution precision.

NWE’s Role in Lingshui 172

Global Supervision for a National Milestone

NWE is trusted to support this strategic project through:

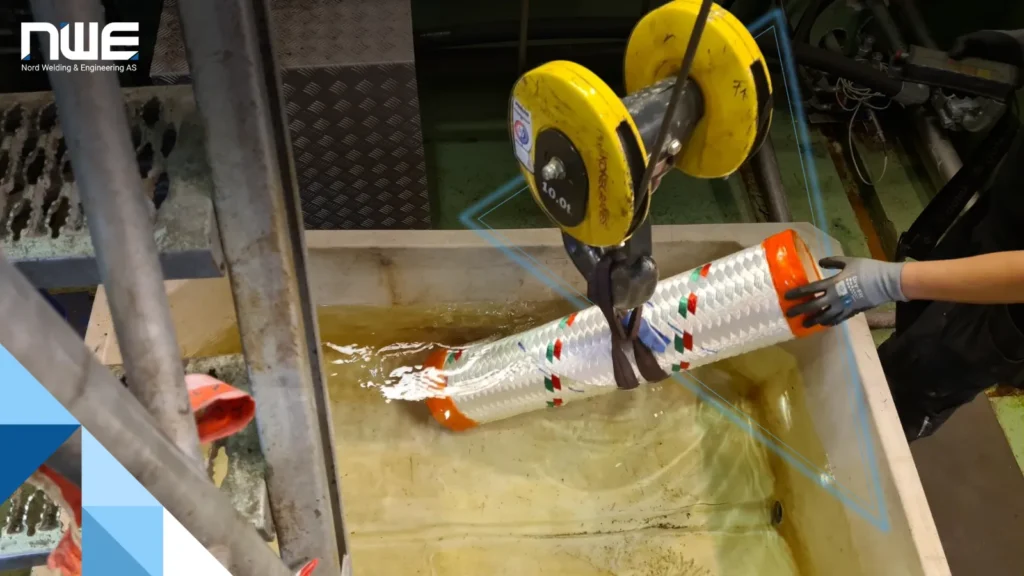

Third-party inspections at fabrication yards for subsea structures, risers, and pipelines

Oversight on coating, welding, and NDT inspections at multiple international sites

Dimensional control and mechanical checks during equipment assembly

Witnessing of FAT and SAT for both subsea and topside systems

Surveillance during loadout, transport, and offshore installation

Full documentation and certification support

Through operations across China, Singapore, Malaysia, Norway, UK, and India, NWE ensures compliance at every link in the supply chain.

China’s First Deepwater Development

A Technological Leap Beneath the South China Sea

The Lingshui 172 field is located 150 km offshore Hainan Island, in water depths exceeding 1,500 meters. Developed with a semisubmersible Floating Production Unit (FPU) and connected to six subsea wells, the field links through umbilicals and flowlines to an onshore terminal, enabling efficient gas export.

Technical Scope & Innovation

Advanced Subsea Engineering for Harsh Environments

Key components of the field’s infrastructure include:

Subsea trees, manifolds, infield pipelines, and risers

Dynamic export pipelines from the seabed to shore

High-spec equipment assembled and qualified across global locations

Facing high-pressure environments and deepwater constraints, the project leverages the latest in subsea and structural design technologies.

Services Delivered by NWE

End-to-End Quality Assurance Across Continents

Inspection of risers, coatings, NDT processes, and welding at vendor sites

Assembly checks for mechanical and dimensional integrity

Full lifecycle surveillance – from fabrication to offshore installation

FAT/SAT witnessing to validate functional performance

Certification and traceability verification

Trusted Oversight for Complex Deepwater Projects

Confidence Delivered Through Independent Expertise

NWE ensures every component meets the highest industry standards — from deep fabrication yards in Asia to offshore installation in the South China Sea — delivering confidence and quality assurance for one of China’s most important energy assets.

How useful was this post?

Click on a star to rate it!

5 / 5. 44