Trion FPU: NWE Supports Deepwater Production in Mexico’s Gulf

Engineering Oversight & Quality Assurance for Mexico’s First Deepwater FPU

Trion represents a landmark milestone in Mexico’s offshore energy—a high-capacity FPU with NWE ensuring engineering excellence and project integrity.

NWE’s Role in Ensuring Engineering & Execution Excellence

Precision Supervision from Fabrication to Offshore Commissioning

NWE played a pivotal role in the Trion Floating Production Unit (FPU) project by delivering expert engineering design appraisals, supervision services, material inspections, and third-party verifications during fabrication, integration, and subsea commissioning stages.

From fabrication yards to final offshore deployment, NWE ensured that every component of the project met the highest standards of safety, quality, and operational performance.

A Breakthrough for Mexico’s Offshore Energy Sector

First Deepwater FPU, Positioned for Long-Term Strategic Impact

Located in the Perdido Basin, around 180 km offshore Mexico at depths of approximately 2,500 meters, the Trion FPU is a game-changer for Mexico’s energy industry. The unit is designed to handle 100,000 barrels of oil per day and over 4 million cubic meters of gas per day, supporting national energy supply and economic development with first oil targeted for 2028.

Fabrication Highlights & Scale

Built for Harsh Deepwater Conditions

Constructed by a leading global fabrication yard, the FPU boasts a semi-submersible structure weighing over 44,000 tons, with dimensions of 94 x 94 x 57 meters. NWE’s presence throughout the fabrication process ensured full compliance with client requirements and international regulations.

Seamless Integration Within a Multi-Contractor Environment

Global Project. Local Expertise.

Trion FPU was executed under a multi-partner model involving global leaders in EPC, installation, drilling, and subsea systems. Within this complex framework, NWE ensured quality alignment, schedule integrity, and technical readiness, acting as the client’s extended technical arm on-site.

NWE’s Scope of Services

From Steel Cutting to First Oil Readiness

Our team oversaw:

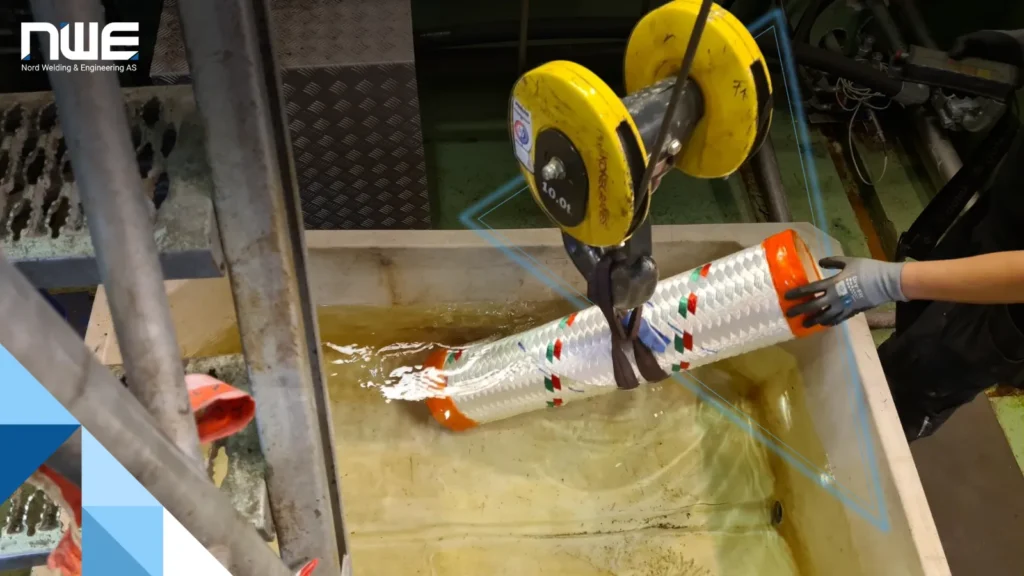

Fabrication yard supervision — structural, mechanical, piping, and welding control

Topside integration inspections — E&I systems, safety compliance, function testing

Marine systems verification — mooring, risers, control systems

Commissioning support — startup readiness and third-party validation

This full-spectrum engagement demonstrates NWE’s ability to support complex offshore developments from start to finish.

A Testament to NWE’s Offshore Expertise

Delivering Certainty in Deepwater Energy Projects

The Trion FPU project stands as a strong example of NWE’s expertise in:

Deepwater operational supervision (2,500 m water depth)

Large-scale semi-submersible fabrication oversight

Cross-disciplinary inspection and validation services

Effective collaboration across international contractor teams

Build Offshore With Confidence — Build With NWE

End-to-End Technical Assurance for High-Value Energy Projects

Whether you’re planning an FPU, FPSO, or subsea infrastructure project, NWE delivers the technical assurance, project discipline, and execution quality your team can rely on.

📩 Reach out today to explore how NWE can support your next offshore development.

How useful was this post?

Click on a star to rate it!

5 / 5. 22