Where agility and reliability meet

NWE provides independent third-party inspection services and separate asset-integrity engineering support, increasing the quality and safety of our clients’ projects, protecting their operations and budgets, while improving environmental performance

NWE | Inspections That Secure Safer Assets and Confident Decisions

NWE Group brings together proven inspection expertise, global certifications, and an agile presence across key energy hubs — to help clients secure safer assets, reduce risk, and make confident decisions in an era of complex challenges and opportunities.

What Makes NWE Stand Out

✔ Global presence with local expertise

✔ Independent, certified, and reliable

✔ Full range of inspection and integrity services

✔ Highly skilled, multidisciplinary team

✔ Proven track record with leading operators

✔ Agile, responsive, and client-focused

✔ Compliance with leading global standards

✔ Every client is a trusted partner

Independent inspections at supplier sites to ensure product quality and compliance.

Final random checks before shipment to verify quality, quantity, and documentation.

Certified weld inspections performed under ISO 17020 for structural integrity.

PED-compliant inspections of pressure equipment by an accredited RTPO team.

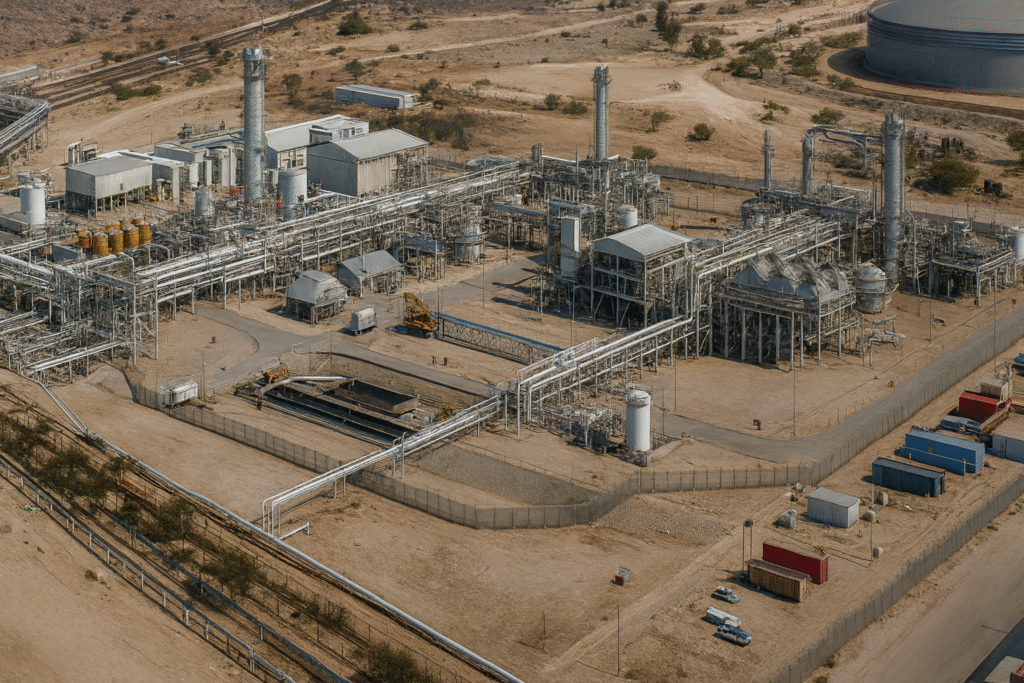

Scheduled inspections of in-use assets to detect wear, corrosion, or failure risks.

ROV-assisted visual inspections of underwater structures, pipelines, and assets.

Expert auditing and supervision of NDT processes to ensure accurate, safe testing.

Complete pipeline integrity evaluations to ensure safe operation, compliance, and extended service performance.

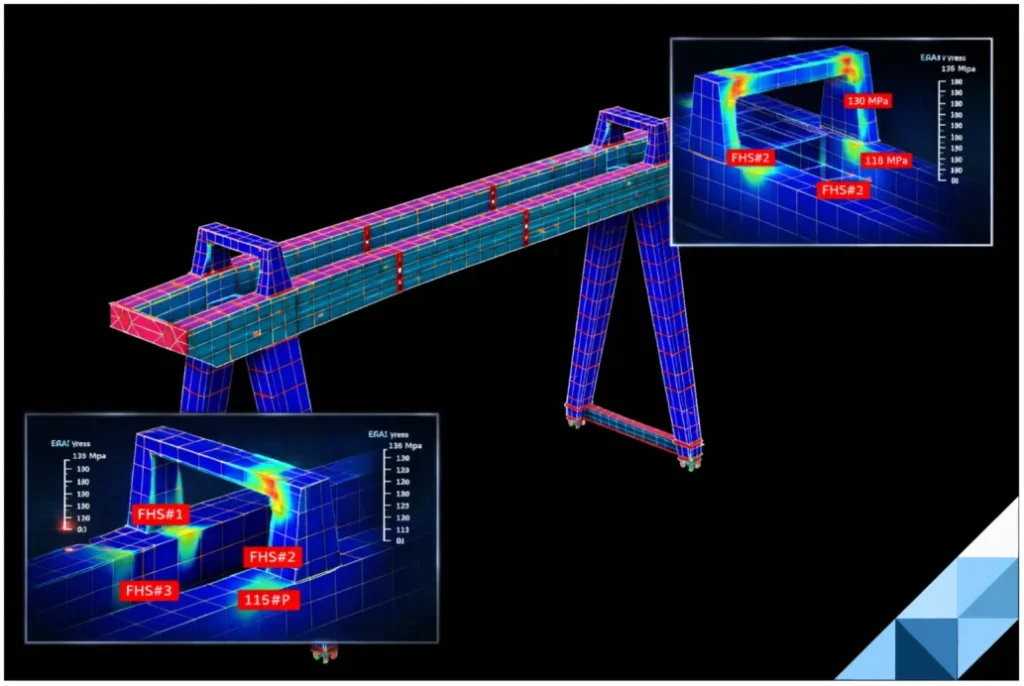

Onshore and offshore structural analysis for fatigue, corrosion, and risk using advanced FEA methods for enhanced safety.

Comprehensive analysis of pipeline stresses to ensure durability, safety, and code compliance in operations.

Stress Analysis for piping and associated structures to ensure operational reliability and compliance.

Finite-element and conventional analysis of structural loads to safeguard integrity under dynamic operational conditions.

Verification and documentation of ‘as-built’ conditions to ensure accuracy against original design specifications.

Engineering Critical Assessments calculating safe operating limits, remaining life, and approval for continued use.

Priority-based inspection planning using risk evaluation to optimize safety, minimize downtime, and extend asset life.

NWE Auditing & Expediting Services

Skilled workforce supply paired with reliable inspection and expediting services to support your operations.

Thorough vendor audits and technical evaluations to verify quality, compliance, and supplier reliability.

Our Projects & Engineering Solutions

Explore real-world projects showcasing our expertise, innovation, and commitment to client success.

Latest News & Events

News that shapes our journey – insights, achievements, and more.