Over the life of a project, small field changes, undocumented tie-ins and buried utilities can make “as-designed” drawings diverge from reality. Relying on outdated documentation increases the risk of clashes, rework, unplanned shutdowns and safety incidents during future revamps or excavation.

NWE’s As-Built Preparation & Validation services help you confirm the true condition of your assets by:

You typically need this service when you cannot fully trust existing drawings or must prove that construction matches design and tolerance requirements.

Common use cases:

NWE focuses on usable outputs and clear governance, not just survey files.

The result is a verified as-built basis for future engineering, integrity assessments and operational decisions.

NWE’s As-Built Preparation & Validation services are applied across:

Point-cloud processing and modelling to produce CAD/BIM-ready deliverables and support scan-to-model and digital-engineering workflows

NWE is more than a survey provider – it is an independent, accredited inspection and asset-integrity engineering company, so as-built data is collected and used with full lifecycle integrity in mind.

Accredited and certified

NWE is accredited under NS-EN ISO/IEC 17020:2012 as an inspection body and operates certified ISO 9001, ISO 14001 and ISO 45001 management systems, ensuring consistent, auditable QA/QC for as-built validation.

Survey, inspection and integrity in one place

As-built preparation and validation are delivered together with inspection, underwater inspection and asset-integrity services, so captured data directly support FFS, structural assessments, pipeline integrity, RBI and inspection planning without duplication.

Governance- and deviation-focused approach

As-built validation is treated as part of QC and tolerance management, linking deviations to MOC, non-conformance handling and compliance, rather than a one-off measurement exercise.

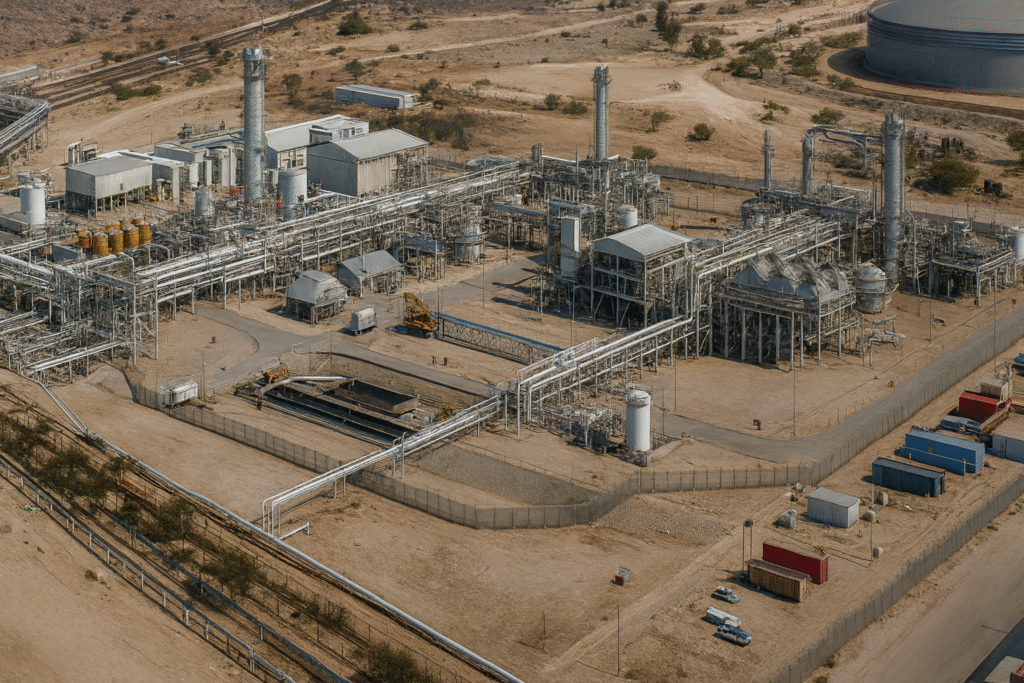

Proven in complex environments

NWE has experience on both onshore facilities and offshore assets where access, safety and uptime are critical, making reliable as-built data a key enabler for planning and risk reduction.

As-Built Preparation & Validation often supports and is supported by other NWE services, including:

Contact NWE or request an As-Built Preparation & Validation package for your project.

Explore real-world projects showcasing our expertise, innovation, and commitment to client success.

As-built preparation is the creation or update of drawings and models so they reflect actual built conditions. As-built validation compares those conditions against approved design and tolerance limits, documents deviations and links them to QA/QC and MOC processes.

Accuracy and tolerance bands are agreed at project start, based on asset criticality and use. Industrial laser scanning typically provides millimetre-level accuracy suitable for clash detection and revamp planning, with tolerances such as ±5–10 mm commonly applied for structural and piping work.

Validated as-built data become a single, trusted reference for FFS, structural and pipeline integrity assessments, RBI, tie-in design and decommissioning planning, helping to reduce surprises, rework and risk on future projects.

We’re excited to connect with you and share more about how we can collaborate together!

Please contact us to discuss your staffing requirements and explore how NWE can assist in achieving your project objectives

NWE provides independent third-party inspection services and separate asset-integrity engineering support—improving quality and safety, protecting operations and budgets, and enhancing environmental performance.