Complete pipeline integrity evaluations to ensure safe operation, compliance, and extended service performance.

Onshore and offshore structural analysis for fatigue, corrosion, and risk using advanced FEA methods for enhanced safety.

Comprehensive analysis of pipeline stresses to ensure durability, safety, and code compliance in operations.

Stress Analysis for piping and associated structures to ensure operational reliability and compliance.

Finite-element and conventional analysis of structural loads to safeguard integrity under dynamic operational conditions.

Verification and documentation of ‘as-built’ conditions to ensure accuracy against original design specifications.

Engineering Critical Assessments calculating safe operating limits, remaining life, and approval for continued use.

Priority-based inspection planning using risk evaluation to optimize safety, minimize downtime, and extend asset life.

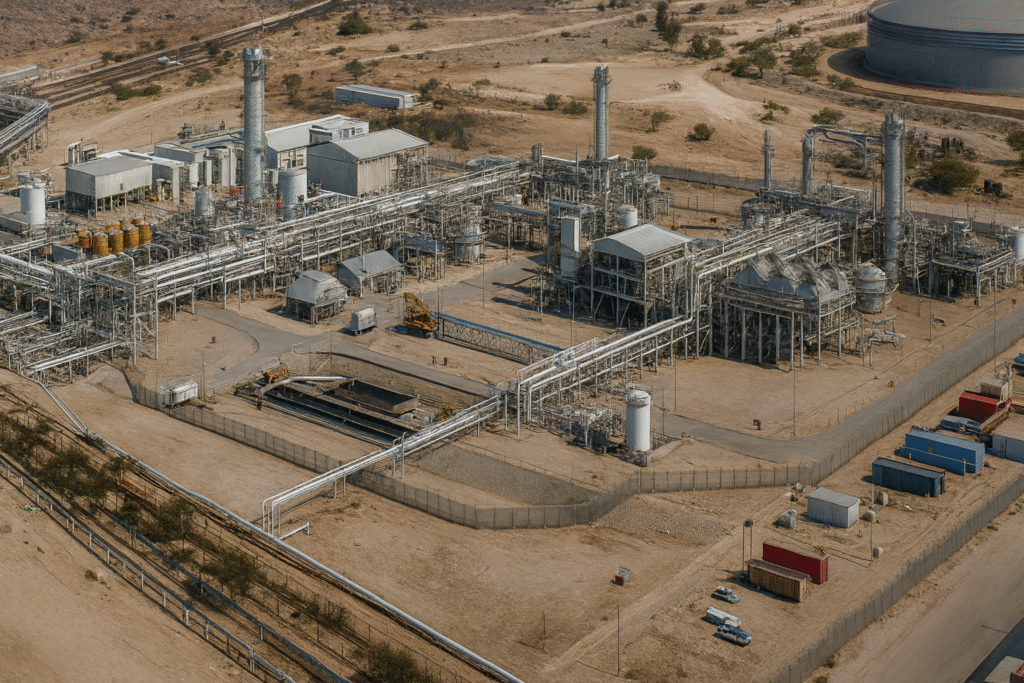

Explore real-world projects showcasing our expertise, innovation, and commitment to client success.

AIM is a structured program to keep assets safe and reliable—combining risk-based planning, targeted assessments and a governed plan with KPIs and reviews. About the team: https://nwegroup.no/about-us/

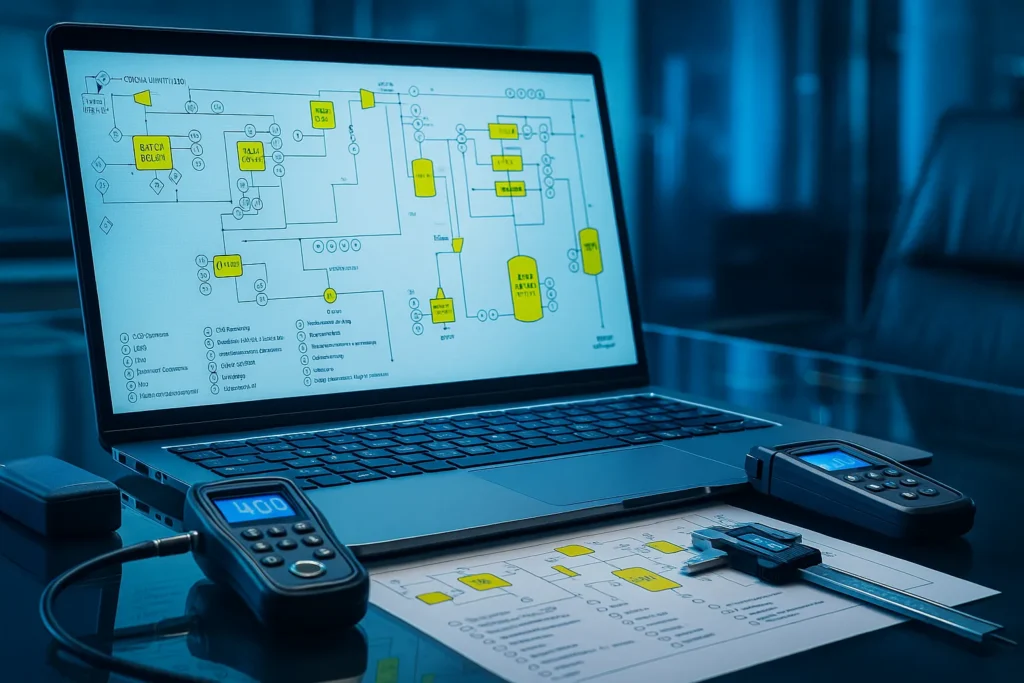

RBI (API 580/581) prioritizes inspection by likelihood and consequence of failure—optimizing techniques and intervals to cut risk and lifecycle cost.

FFS evaluates defects (e.g., thinning, cracks, dents) to decide run, derate, repair, or replace—supporting safe continued service with quantified margins.

P&IDs, design/MDR data, service history, prior inspections, corrosion/repair records, and operating envelopes. Clean data accelerates modeling and decisions. Contact: https://nwegroup.no/contact-us/

For a focused unit, baselining can be completed in weeks; scope, data quality, and workshops set the exact timeline in our proposal. About NWE: https://nwegroup.no/about-us/

Piping/pipeline stress analysis checks code compliance and loads at supports/nozzles, preventing overstress and feeding mitigations into the integrity plan

It identifies threats, evaluates risk, and sets mitigations—inspection, repairs, pressure management and monitoring—integrated into the AIM plan. Start a conversation: https://nwegroup.no/contact-us/

Discovery → data preparation → RBI model → targeted assessments (e.g., FFS) → integrity plan with inspection strategy, mitigations, KPIs, and review cycle. About NWE: https://nwegroup.no/about-us/

A governed integrity plan: risk register, inspection program, mitigation actions, KPIs, and a review cadence—linking engineering to availability and safety targets. Accreditation: https://nwegroup.no/certificate/

Share asset lists, design/inspection data, and objectives. We’ll scope an AIM program with schedule, deliverables, and governance, then mobilize. Contact: https://nwegroup.no/contact-us/

We’re excited to connect with you and share more about how we can collaborate together!

Please contact us to discuss your staffing requirements and explore how NWE can assist in achieving your project objectives

NWE provides independent third-party inspection services and separate asset-integrity engineering support—improving quality and safety, protecting operations and budgets, and enhancing environmental performance.