Essentials

- Right inputs → Defensible RBI: map asset/service, damage mechanisms, rates, history, conditions, inspection data, and data confidence.

- API 581 = POF×COF to plans: quantify risk and set justified intervals and scopes.

- Govern updates: clear triggers (process changes, incidents, standards) keep programs audit-ready.

- Optimize cost vs risk: cut over-inspection without missing real threats.

- Own the data: assign Data Owners and track Confidence (A/B/C) for every field.

What is API 580? A governance framework for implementing Risk-Based Inspection (RBI)—roles, data requirements, decision process, and update cycles. API 580

What is API 581? A quantitative method that converts inputs into Probability of Failure (POF) and Consequence of Failure (COF) to produce risk rankings and inspection intervals. API 581

Why RBI Data Quality Defines Asset Integrity

Strong RBI data requirements are the first defense against model uncertainty. When inputs are incomplete, inconsistent, or low-confidence, errors cascade through API 581 POF × COF calculations, weakening the risk matrix and the credibility of any RBI inputs checklist you use.

What goes wrong with poor data

- Over-inspection: inflated cost with little safety gain.

- Under-inspection: missed degradation and elevated failure risk.

- Compliance risk: auditors challenge the validity of RBI decisions.

How to keep the model defensible

- Build governance for data collection, validation, and traceability (who owns what, where it lives, how it’s verified).

- Label Data Confidence (A/B/C) and Source (measured/estimated/assumed) for every critical field.

- Close gaps before modeling; if not possible, use conservative assumptions and document them.

- Cross-link decisions to the service page [Risk-Based Inspection (RBI)] so stakeholders can see method-to-plan alignment.

Build a Risk Model You Can Defend: The RBI Inputs That Matter

Asset & Service Context — Set the Baseline

Design code, material grade, pressure/temperature, service fluid, and environment define initial susceptibility. Tie asset tags and corrosion circuits to a single source of truth. For method alignment, see [Risk-Based Inspection (RBI)] and [Risk-Based Integrity on a Budget: Cost–Benefit Playbook for Pipeline IM ]

Damage Mechanisms & Rates — Quantify What Degrades

Map credible damage mechanisms (general corrosion, SCC, erosion, fatigue) per service. Use measured or modeled corrosion/leak rates; document assumptions. Wrong DM ⇒ wrong POF. Cross-check terminology with [What Is Pipeline Inspection? Methods, Benefits & Standards] if you’re harmonizing vendor data.

History & Reliability Records — Ground Truth for POF

Use failure logs, leak/repair records, inspection history (UT/RT/VT), and maintenance actions to validate or challenge model assumptions. Close coverage gaps; stale history = artificial confidence.

Data Confidence & Sources — Make Uncertainty Visible

Label Data Confidence (A/B/C) and Source (Measured/Estimated/Assumed) for every field. Where gaps persist, apply conservative assumptions and flag them as formal Update Triggers for your next review.

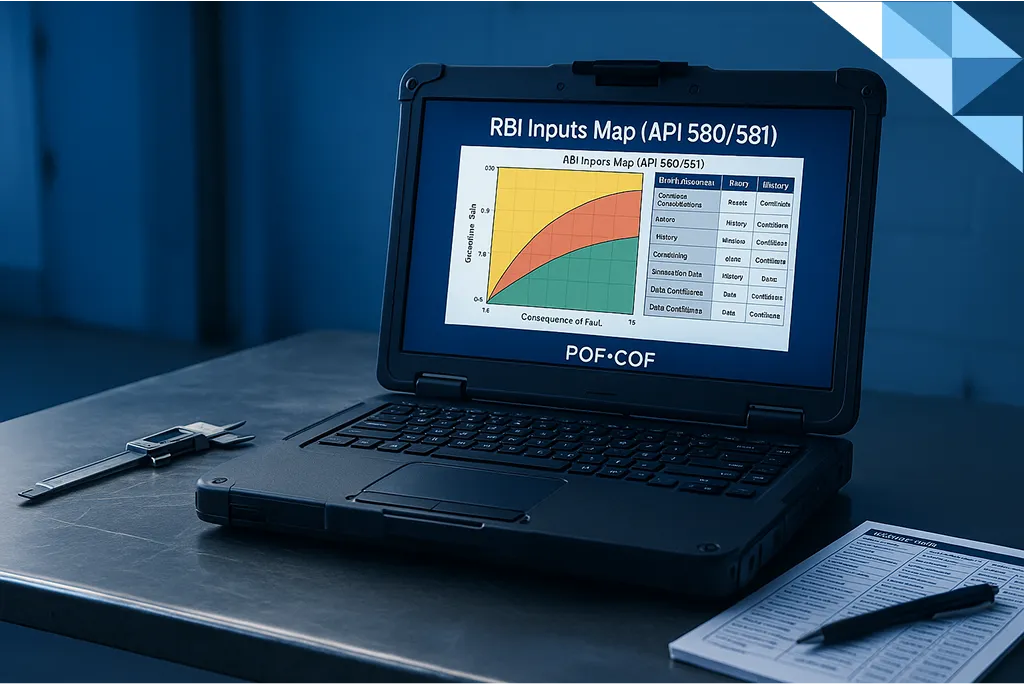

RBI Inputs Map (caption: “API 580/581 RBI inputs checklist mapping to POF×COF”)

Alt text: “RBI Inputs Map linking asset/service context through inspection history and data confidence to API 581 POF×COF.”

| Input Category | Examples | Impact on RBI | Data Owner | Confidence (A/B/C) | Source (M/E/A) |

| Asset & Service | Design code, material, rating, circuit | Baseline susceptibility & circuitization | Integrity/Design | A/B/C | M/E/A |

| Damage Mechanisms | Corrosion, SCC, erosion, fatigue | Selects degradation pathways that drive POF | Corrosion Eng. | A/B/C | M/E/A |

| Corrosion/Leak Rates | UT trends, coupons/probes, models | Direct numeric input to POF | Inspection/Corrosion | A/B/C | M/E/A |

| Failure/Incident History | Leaks, near-misses, breakdowns | Validates/challenges assumptions; credibility | Operations/HSE | A/B/C | M/E/A |

| Operating Conditions | Pressure, temperature, flow, contaminants | Triggers mechanisms; affects progression | Operations/Process | A/B/C | M/E/A |

| Inspection History | UT/RT/VT results, coverage gaps | Evidence base to recalibrate risk | Inspection | A/B/C | M/E/A |

| Data Quality | Completeness, traceability, version control | Uncertainty → safety factors & governance needs | RBI Coordinator | A/B/C | M/E/A |

From POF × COF to Actionable Intervals — Turn Risk into Schedules

Under API 581, Probability of Failure (POF) × Consequence of Failure (COF) yields risk categories that must translate into scope + interval + justification (documented in your decision log).

Translate the Risk Matrix into Plans

- High POF + High COF → Inspect/mitigate now; evaluate repair/re-rate; log management of change.

- Low POF + High COF → Conservative intervals; add monitoring/condition checks; leadership visibility.

- High POF + Low COF → Focused scopes; short-cycle NDT; check repair economics before overhaul.

- Low POF + Low COF → Longer intervals with governance gates; keep triggers defined.

Refresh with Confidence: Update Triggers & Governance

RBI is not a one-time exercise. API 580 requires programs to remain dynamic, adjusting to real-world changes. Decision-makers should ensure updates are triggered by:

Operating Changes & Incidents

- Start-up/shutdown cycles, debottlenecking, or process upsets.

- Any leak, rupture, or near-miss event.

Regulatory & Standard Updates

- Alignment with the latest API 580/581 revisions, ASME, or DNV rules.

- Regional authority mandates (EU PED, CIS codes, MEA regulators).

Governance & Accountability

- Clear ownership of data stewardship (inspection, operations, reliability).

- Scheduled internal reviews (e.g., annual RBI audit, 3-year revalidation).

- Documented decision logs to prove compliance during external audits.

Strong governance reassures executives and regulators that RBI is not just an algorithm—it is a controlled management process.

Practical Steps for Decision-Makers

Executives don’t need to run the math themselves—but they must ensure the right process is in place. Key actions include:

- Validate input quality: Confirm that RBI inputs are complete, consistent, and traceable.

- Run an RBI readiness check: Benchmark current practices against API 580 requirements.

- Align with operations: Ensure inspection planning is linked to maintenance and production schedules.

- Plan periodic reviews: Establish fixed governance cycles for revalidating RBI models.

- Track outcomes: Use KPIs (cost savings, reduced failures, compliance audit results) to prove value.

When leaders make these steps part of their asset integrity strategy, RBI moves from being a compliance exercise to a performance lever.

Next Steps with NWE

At NWE, we support operators, EPCs, and regulators across EU/MEA/CIS with executable RBI programs. Our approach combines API 580 governance with API 581 quantitative modeling, ensuring defensible, cost-effective inspection strategies.

- Book an RBI Readiness Review with our integrity engineers. See [Risk-Based Inspection (RBI)]

- Request a 30-min technical call to discuss your current RBI gaps.

- Send us an RFP and benchmark NWE’s methodology against your current program.

Frequently Asked Questions (FAQ)

Q1. What is the difference between API 580 and API 581?

API 580 provides the governance framework for implementing RBI, while API 581 defines the quantitative methods to calculate POF×COF and inspection intervals.

Q2. Why is data quality so critical in RBI?

Low-confidence or incomplete data undermines the RBI model, leading to either wasted inspection spend or unrecognized risks.

Q3. What are the main data requirements for API 580/581?

Asset and service data, operating conditions, damage mechanisms, failure history, inspection history, and data confidence levels.

Q4. How often should RBI assessments be updated?

RBI re-assessment is not time-based; each equipment or system has its own plan.

Q5. How do POF and COF combine into actionable plans?

API 581 uses risk matrices (POF×COF) to set inspection intervals, scope, and mitigation strategies.

Q6. What role does governance play in RBI?

Governance ensures accountability, traceable decision-making, and regulatory compliance across the RBI lifecycle.

Q7. Can RBI help reduce costs as well as risk?

Yes. By aligning inspection scope to actual risk, RBI eliminates unnecessary work while maintaining safety.

One Response

If you wish for to improve your experience only keep

visiting this site and be updated with the newest news update posted here.