NWE has successfully completed a internal inspection of a reinforced concrete water tank using a Blueye X3 ROV—without draining or interrupting operations. The project demonstrates how non-intrusive inspection methods can deliver reliable asset condition data while keeping facilities in service.

Pilot ROV Inspection of Concrete Water Tank

The inspection confirmed that walls and columns are in generally good shape, with no major cracks observed. However, several key issues were identified:

-

Sealant deterioration: widespread failure at floor joints, likely causing leakage.

-

Corrosion: severe rusting on ladders, hatches, and pipes.

-

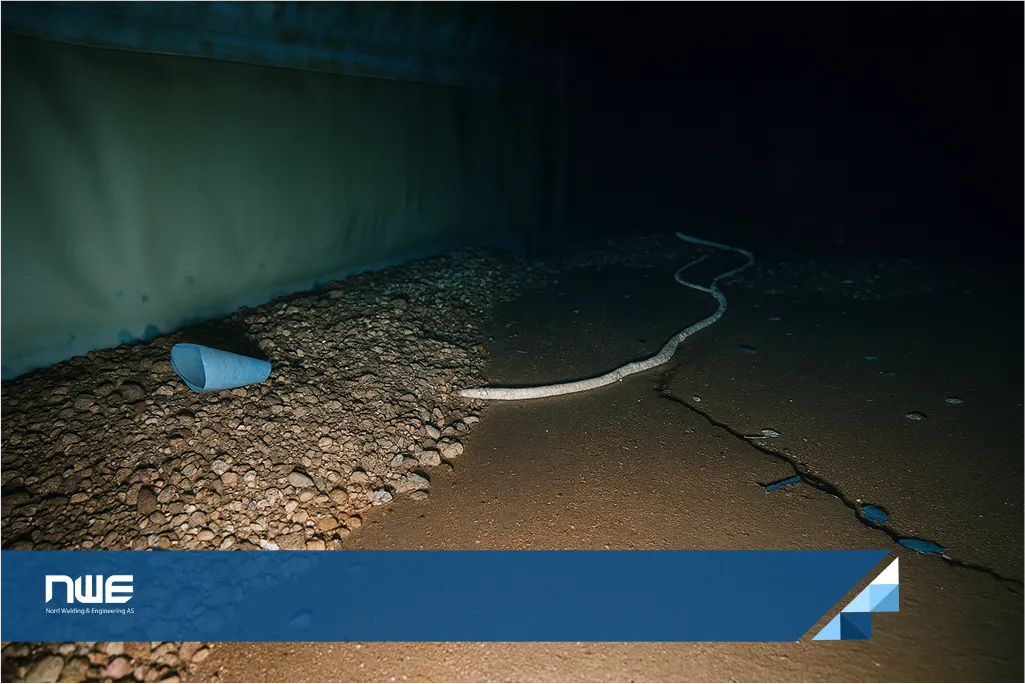

Sediment build-up: sand and gravel deposits increasing contamination risk.

-

Damaged curtains: torn internal barriers reducing performance.

Recommendations:

NWE advises immediate repair of floor sealants, renewal of protective coatings, sediment removal, and replacement of corroded metallic components. Establishing routine ROV inspections will further enhance long-term asset reliability.

Closing line:

This confirms NWE’s ability to deliver fast, safe, and evidence-based tank inspections—helping operators maintain integrity without taking assets out of service.

NWE provides professional underwater inspection services to ensure asset integrity. Contact us to discuss your inspection needs and explore more of our executed projects.