Introduction — Why This Matters

Inspection strategy isn’t just about following a calendar. It’s about balancing safety, risk, and cost.

- Too frequent → wasted budget.

- Too late → failures, downtime, or compliance issues.

This guide shows you how to decide between Risk-Based Inspection (RBI) and Time-Based Inspection (TBI) in a way that is practical, defensible, and aligned with standards.

By the end, you’ll know:

- The trade-off: fixed schedules (TBI) vs risk-driven planning (RBI).

- When TBI is enough (stable conditions, low risk, mandated intervals).

- When RBI adds value (variable service, data gaps, higher consequences).

- How to defend decisions so they survive audits and align your team.

👉 In short: you’ll be able to pick the right method for each asset, justify it clearly, and avoid both over- and under-inspection.

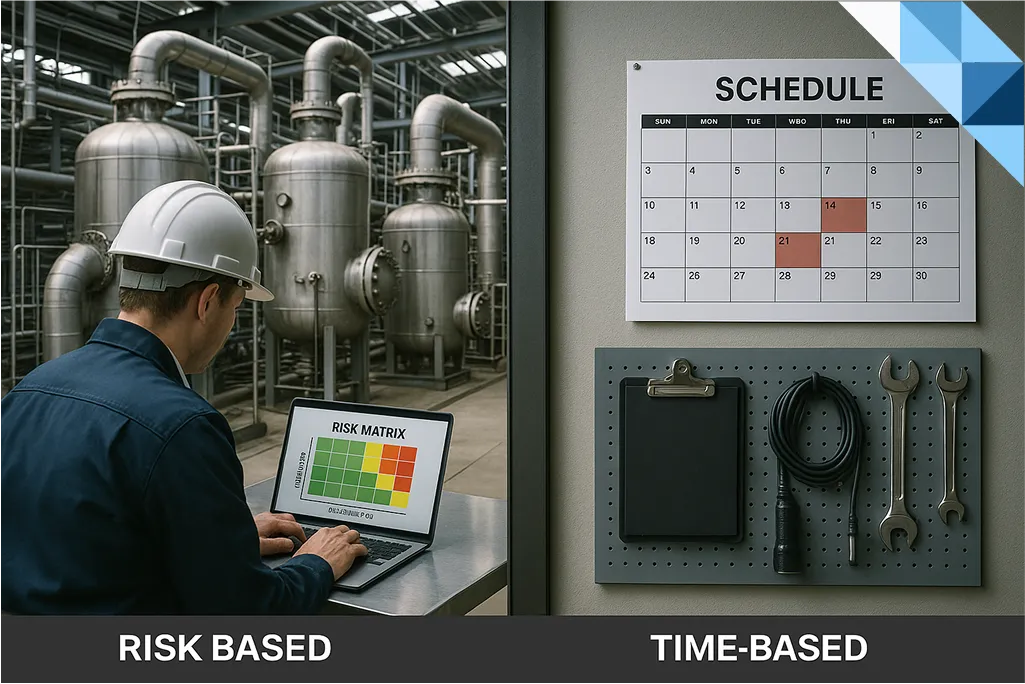

RBI vs TBI: What They Mean and When Each Applies

Risk-Based Inspection (RBI): Driven by risk = Probability of Failure × Consequence of Failure. Focuses on the right place, at the right time, with the right method.

Time-Based Inspection (TBI): Follows a fixed calendar or statutory frequency. Works best when conditions are stable and predictable.

👉 Key difference:

- TBI asks: “Did we inspect on time?”

- RBI asks: “Did we inspect where and how it mattered most?”

When Time-Based Inspection is Acceptable

TBI works well when:

- Damage mechanisms are stable and well understood.

- Consequences of failure are low, with safeguards in place.

- Long operating history shows consistent performance.

- Regulations already mandate conservative intervals.

When Risk-Based Inspection Adds Value

RBI is the better choice when:

- Damage mechanisms vary or service conditions change.

- Consequences are higher (safety, environment, production).

- Data gaps exist and inspections are needed to reduce uncertainty.

- Multiple assets must be optimized beyond simple compliance.

- Stakeholders need a clear rationale for inspection budgets and timing.

👉 RBI helps companies spend inspection money where it matters most.

Data Requirements (RBI vs TBI)

The inspection approach depends on the data available.

RBI needs more and deeper data:

- Known damage mechanisms (corrosion, cracking, erosion).

- Inspection effectiveness (how reliable past inspections were).

- Condition trends (thickness readings, anomalies, records).

- Operating history & IOWs (pressure, temperature, excursions).

- Consequences (safety, environment, production, compliance).

TBI needs less data, but only works if conditions are predictable:

- Stable service with no major changes.

- Historical proof that failures are unlikely.

- Basic compliance documentation.

👉 Summary: RBI = data-rich, flexible, risk-optimized.

TBI = simpler, but only safe in stable, low-risk situations.

Governance & Reporting — Making Strategies Audit-Ready

Whether you choose RBI or TBI, the program must stand up to audits and reviews. That’s where governance comes in:

- Clear ownership: Every dataset and decision should have a named owner.

- Validation: Make sure inspection data is calibrated, consistent, and reviewed by SMEs.

- Approvals: Engineers, QA/QC, and management should all sign off so risk acceptance is shared.

- Documentation: Keep reports, memos, and assumptions traceable. Regulators and partners expect a clear paper trail.

- Change management: If service conditions change, an anomaly appears, or an excursion occurs, the strategy must be revalidated.

👉 Bottom line: Governance is what turns RBI/TBI from a schedule into a defensible inspection program.

Worked Example — RBI vs TBI in Practice

Consider a process unit with two very different circuits:

Circuit A — Stable Header (Low Risk)

- Corrosion rate is very low (Remaining Life ≈ 16 years).

- Stable operating history with no major excursions.

- TBI outcome: A 3-year calendar-based interval is acceptable.

- RBI outcome: PoF = 2, CoF = 2 → risk is low. The interval can be safely extended to 5 years, saving cost without adding risk.

Circuit B — Hot Transfer Line (High Risk)

- Corrosion rate is faster (Remaining Life ≈ 4 years).

- Two recent excursions increased the damage rate.

- Coverage only medium; some uncertainty remains.

- TBI outcome: A 3-year interval would consume most of the remaining life, leaving the risk unmanaged.

- RBI outcome: PoF = 4, CoF = 4 → high risk. RBI recommends a shorter 1-year interval with targeted inspections, reducing uncertainty and keeping risk controlled.

Decision:

- Apply TBI for Circuit A, where conditions are stable.

- Apply RBI for Circuit B, where risk is higher and uncertainty exists.

- Result: a hybrid strategy — compliance where it’s enough, RBI where it adds value.

👉 This illustrates how RBI and TBI complement each other rather than compete.

RBI vs TBI — Side-by-Side Comparison

| Dimension | Risk-Based Inspection (RBI) | Time-Based Inspection (TBI) |

| Objective | Optimize inspections based on risk (PoF × CoF). | Meet fixed calendar or statutory frequency. |

| Data Needs | Damage mechanisms, inspection effectiveness, wall-thickness trends, IOWs, and consequence data. | Proven stable service, vendor or code schedule, past inspection history. |

| Intervals | Modeled using API 581 (PoF growth, detection effectiveness, CoF thresholds). | Pre-set by regulation or policy. |

| Governance | Strong — validation, peer review, SME sign-off. | Lighter — simply meet cadence. |

| Cost Profile | Higher upfront analysis → long-term savings. | Predictable but may lead to over- or under-inspection. |

| Best Fit | Variable conditions, higher consequences, multi-asset optimization. | Stable mechanisms, low risk, mandated frequencies. |

| Risks if Misapplied | False precision if the data is poor. | Missed risks; unsafe if service changes. |

👉 Takeaway: RBI is not always “better” than TBI — each has its place.

FAQ — Short Answers to Common Questions

Is RBI always better than TBI?

No. TBI works fine when conditions are stable, risk is low, and statutory intervals already cover safety. RBI adds value when risk is higher, conditions vary, or data gaps exist.

What extra data does RBI need?

RBI requires risk drivers: defined damage mechanisms, inspection effectiveness, wall-thickness trends, IOW history, and consequence data. TBI only needs proof that a fixed schedule is still safe.

How are inspection intervals set under RBI?

Intervals are modeled using API 581, based on:

- How fast degradation happens (PoF growth).

- How effective inspections are at detecting damage.

- How severe the potential consequences are (CoF).

When is Time-Based Inspection defensible?

When equipment has stable service, long remaining life, low consequence of failure, and regulations already mandate safe intervals.

How often should the risk matrix be updated?

- High-risk assets: at least annually.

- Low-risk assets: every 2–3 years.

- Anytime after a duty change, anomaly, or major excursion.

- After every inspection, maintenance, or repair.

What if there are data gaps?

Start with shorter intervals, use targeted inspections, and document uncertainties until more data is gathered. RBI can then extend intervals with confidence.

Which approach saves more cost long-term?

RBI usually delivers savings by optimizing intervals and avoiding unnecessary inspections — but only if the input data is strong and well-validated.

Conclusion & Next Steps — How to Decide and Move Forward

Recap:

- Use TBI when conditions are stable, risk is low, and statutory intervals already provide safety.

- Use RBI when risks vary, data is incomplete, or optimization can reduce cost and exposure.

- In all cases, inspection intervals must be traceable to data, assumptions, and approvals — that’s what makes them defendable in audits.

- When the damage mechanisms are clear and the damage rate is time-dependent, this supports a defendable interval selection.

Practical Next Steps:

- Define a simple PoF/CoF rubric so teams apply risk scoring consistently.

- Validate inputs — confirm mechanisms, inspection effectiveness, IOWs, and consequence data.

- Pilot RBI on one high-risk unit to demonstrate value and governance discipline.

- Document triggers for switching strategy (duty changes, excursions, anomalies).

- Engage expertise (e.g., NWE) to align with API 580/581 and ensure audit-ready governance.

👉 Final message: Don’t think of RBI and TBI as rivals. Think of them as tools — use each where it fits, and your inspection program will be safer, leaner, and defensible.

One Response